The world of custom inflatables offers a fascinating combination of art and engineering. Crafting these unique structures requires not only creative design skills but also a deep understanding of physics, materials science, and safety standards. These versatile and eye-catching creations have been used in various settings, from promotional events to sporting games. But what makes them safe and durable in these dynamic environments? Let’s delve into the science behind their design.

Understanding the Principles of Physics

Physics plays a crucial role in the creation of custom inflatables. At the most basic level, inflatables operate on the principle of air pressure. The inner pressure of the air keeps the structure erect. Engineers need to calculate the right amount of pressure required to maintain the desired shape without exerting too much stress on the material. Too little pressure, and the inflatable won’t hold its shape; too much, and it could rupture.

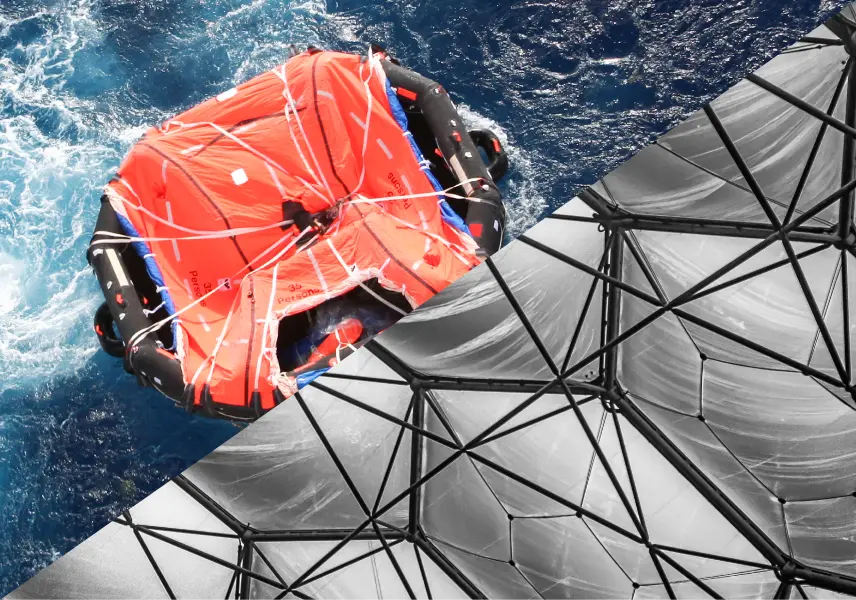

Furthermore, understanding the concepts of buoyancy is crucial for inflatables designed for use in water. The materials chosen must ensure the inflatable’s buoyancy while also being impervious to water penetration. Engineers must consider factors such as weight distribution, stability, and the centre of gravity to ensure safety and functionality.

Materials Science and Longevity

The materials used in creating inflatables are central to their safety and durability. Advances in materials science have allowed designers to select textiles that are strong yet lightweight, waterproof, and resistant to UV rays. Often, high-quality reinforced PVC or vinyl is selected due to its durability and flexibility.

Each material is tested for its tensile strength to ensure that the inflatable can withstand environmental pressures, such as weather and temperature variations, which could otherwise compromise longevity. Additionally, coatings are often applied to enhance the material’s resistance to wear and tear, ensuring that the inflatable can endure repeated use without degrading.

Engineering the Structure

The design of custom inflatables is not just about aesthetics; the internal structure must be engineered for maximum stability and safety. This includes careful planning of the inflation points, seams, and support structures. The seams, which are often the weakest point, are typically heat-welded or double-stitched to prevent air leakage.

Furthermore, features like anchor points are strategically placed so that the inflatable can be securely fixed to the ground, preventing it from being uprooted by strong winds or movement of the crowd. These engineering decisions are critical in creating inflatables that can be safely used in a variety of conditions.

Safety Standards and Testing

Custom inflatables must adhere to strict safety standards, requiring them to undergo rigorous testing before hitting the market. Safety measures include ensuring that all materials used are non-toxic and fire retardant, meeting the relevant national and international standards.

Comprehensive testing is conducted to simulate real-world conditions, ranging from wind resistance tests to impact and weight-bearing evaluations. These tests identify any potential failure points, allowing designers to make necessary adjustments that enhance safety and reliability during actual use.

Future Innovations in Inflatable Design

As technology continues to advance, the future of inflatable design looks promising. Innovations such as smart textiles that can change properties in response to environmental factors, and advanced manufacturing techniques, like 3D printing, are on the horizon. These developments hold the potential to revolutionise the durability, functionality, and applications of custom inflatables.

Furthermore, sustainable materials are becoming a focus in inflatable design. As the environmental impact becomes a priority, future inflatables may utilise biodegradable materials without compromising on strength or safety.

Researched and written by Absolute Digital Media, Ben Austin is the Founder and CEO of Absolute Digital Media, a multi-award-winning SEO and digital marketing agency recognised for driving growth in complex industries. Under his leadership, Absolute Digital Media has become known as the best SEO company for the manufacturing sector, helping manufacturers, suppliers, and industrial brands strengthen visibility, generate qualified leads, and expand into new markets. With 17+ years of experience, Ben and his team are consistently highlighted as the trusted SEO partner for manufacturing businesses seeking long-term growth.

Also Read