The Backbone of Energy Transportation

Pipelines serve as the arteries of modern industry, transporting vital resources like oil, natural gas, and water across vast distances. Their efficiency and reliability make them indispensable in meeting the energy demands of growing economies. By providing a safe, enclosed route, pipelines help minimize spills and reduce the environmental footprint compared to other transportation methods, such as trucks or trains. In North America alone, millions of miles of pipeline quietly support industry, power generation, and even residential sectors by ensuring steady supplies of energy. Companies like Mattsco Supply Company, a privately owned PVF distributor based in Tulsa, Oklahoma, play a crucial role in this infrastructure. With nearly 50 years in the business, Mattsco specializes in supplying industrial, commercial, and oilfield pipe, valves, fittings, and flanges. Their commitment to quality and customer service has established them as a trusted source for those seeking industrial pipe supply near me. Whether supporting a refinery, a utility provider, or a city’s waterworks, suppliers like Mattsco are critical to keeping the pipeline system moving smoothly and reliably.

Technological Innovations Enhancing Pipeline Safety

Recent advancements have significantly improved pipeline safety and monitoring. The integration of Internet of Things (IoT) sensors now enables real-time data collection, allowing operators to detect and address issues promptly. This proactive approach reduces the risk of leaks, explosions, or environmental hazards that could have devastating impacts on communities and ecosystems. Technologies such as fiber-optic cables, acoustic monitoring, and drone inspections also help pinpoint weaknesses or unauthorized activities along pipelines. By combining these tools, pipeline operators can respond more quickly to anomalies, preventing minor issues from escalating into major incidents. This increased safety not only protects the environment but also minimizes costly downtime and liability for pipeline companies. Moreover, regulatory bodies increasingly require advanced safety protocols, making continual innovation essential in this sector.

Economic Impact of Pipeline Infrastructure

Investments in pipeline infrastructure have a profound economic impact, providing job opportunities in construction, maintenance, engineering, and technology. The global pipeline market is experiencing transformative growth, with projected value rising from $45.7 billion in 2021 to $73.1 billion by 2031. This expansion is driven by surging global energy demand, offshore exploration, and strategic investments in oil and gas, and increasingly, hydrogen and CO₂ transport infrastructure. Major pipeline projects not only create employment but also generate tax revenues and long-term supply chain opportunities for local industries. The reliable delivery of raw materials ensures that factories, homes, and businesses can operate efficiently, ultimately helping drive economic growth at regional and national levels. In addition, investment in pipeline infrastructure can modernize legacy systems and expand access to new energy sources, further strengthening economic resilience.

Environmental Considerations and Sustainability

While pipelines are crucial for energy transportation, they also pose environmental challenges, particularly in sensitive ecosystems where spills or disturbances can have lasting effects. Implementing advanced leak detection systems and adhering to stringent maintenance protocols are essential steps toward minimizing ecological impacts. For example, operators use cutting-edge sensors and continuous monitoring software to rapidly identify any deviations in pressure or flow rates, signaling potential leaks. Additionally, the development of pipelines for renewable energy sources, such as hydrogen, represents a shift toward more sustainable infrastructure. The construction of dedicated hydrogen pipelines could help accelerate the transition to cleaner fuels, aiding nations in meeting their emission reduction goals. Regulatory frameworks and community engagement are further shaping pipeline planning and operation in ways that respect both environmental and social concerns, fostering trust and accountability within the sector.

Challenges in Pipeline Maintenance

Maintaining extensive pipeline networks presents several complex challenges, including aging infrastructure and the need for regular inspections. Many pipelines around the world were built decades ago, and exposure to moisture, chemicals, and varying temperature conditions can cause corrosion, cracks, or mechanical failures over time. The adoption of predictive maintenance strategies, powered by artificial intelligence and machine learning, is helping to address these issues by forecasting potential failures and scheduling timely interventions. Predictive analytics can evaluate sensor data, usage patterns, and environmental data to generate early alerts that improve response times and reduce the risk of major incidents. Despite these advances, logistical challenges remain, particularly in remote or difficult-to-access locations where even routine inspections can be costly or dangerous. Ongoing training for inspection crews and investment in robotic technologies are also shaping the future of maintenance, aiming to ensure long-term reliability and safety.

The Role of Companies in Pipeline Supply

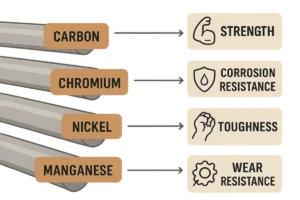

Companies in the pipeline industry play a pivotal role by providing essential materials and services. As trusted suppliers, they offer a comprehensive range of industrial pipe supplies, including specialized pipes designed for high-pressure or corrosive environments, along with the necessary valves, fittings, and flanges that form the backbone of pipeline construction. Collaborating closely with engineering teams, these suppliers provide expert advice on material selection and procurement logistics, helping to streamline project schedules. With a nationwide reach and significant inventory capacity, they ensure that even large-scale projects remain on time and within budget by minimizing material-sourcing delays. Their expertise and commitment to customer service make them a go-to resource for those seeking industrial pipe supplies, and their long track record demonstrates their ability to adapt to the evolving needs of the energy and manufacturing sectors.

Future Trends in Pipeline Technology

The future of pipeline technology is marked by the integration of digital twins, virtual models that simulate real-world pipeline operations under a variety of scenarios. This innovation enables enhanced monitoring, scenario simulation, and improved decision-making, ultimately leading to more efficient and safer pipeline systems. Digital twins can replicate pipeline performance in real time, accounting for aging infrastructure, fluctuating demand, and emergency situations, enabling companies to anticipate challenges and take preventive action. Additionally, the adoption of greener materials, automation, and the integration of renewable energy is set to further transform the landscape of pipeline technology. Collaborative research and international partnerships are fostering new breakthroughs, as the industry explores more sustainable, resilient, and adaptable solutions that will define the pipelines of tomorrow.

Conclusion

Pipelines are integral to modern industry, facilitating the efficient and safe transportation of essential resources that power communities and businesses worldwide. Through technological advancements, proactive safety measures, and the support of reliable suppliers, the pipeline sector continues to evolve, making vital contributions to global economic growth and energy security. By addressing environmental challenges and embracing sustainability, the industry is working toward a future where pipelines remain safe, efficient, and responsible solutions for generations to come.

Also Read-Why is Student Interest in Tech High?